$2,015.00

Model: BS-KS-18

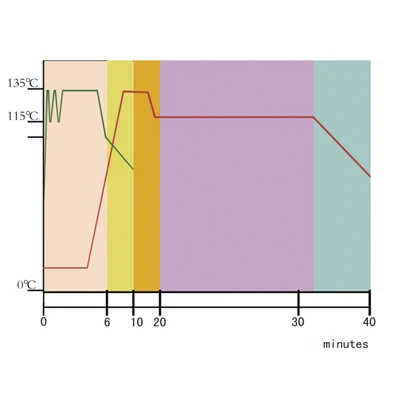

The sterilizer is mainly used for sterilization ophthalmology, dentistry, gynecology and other small devices. Sterilization is the speed and ease of use in mind we have designed. The product is only 2-3 minutes to heat up to 135 degrees both, than sterilizer on the market greatly reducing the heating time, improve

work efficiency. Use also provides a very convenient and simple operation, users can set

Description

Fast Mini Cassette Pressure Steam Autoclave (1.8L)

| Model | BKS-2000 | BKS-5000 | BKS-6000 |

| Capacity | 1.8L | 5.2L | 6.0L |

| Chamber Size(W*D*H)mm | 280*180*38 | 380*180*78 | 480*180*78 |

| External Size(W*D*H)mm | 570*415*170 | 580*460*190 | |

| Temp. Range | 115℃~135℃ | ||

| Temp. Fluctuation | ≤±5℃ | ||

| Ambient Temp. | 5~40℃ | ||

| Working Pressure | 42 kPa ~212kPa | ||

| Chamber Material | 304 Stainless Steel | ||

| Water Tank Volume | 3.4 L | ||

| Standard Accessories | Instrument loading tray*1, Waste water tank*1Drain hose*1, Printing paper*2 | ||

| Power Supply | AC 220V/110V±10%, 50Hz/60Hz | ||

| Packing Size(W*D*H)mm | 580*580*700 | ||

| Net Weight (kg) | 34 | 46 | |

| Gross Weight (kg) | 49 | 61 | |

Features:

1. It only takes 6-7 minutes for the shortest sterilization cycle which can extend service life of the instrument

2. Three shortcut keys for sterilization programs, the sterilization temperature and time can be set freely

3. Alarm for unqualified water and water shortage, the autoclave will stop working when there is a low temperature and low pressure

4. Small dimension, light weight, easy to operate, the cassette can be also used for instrument transfer and temporary storage

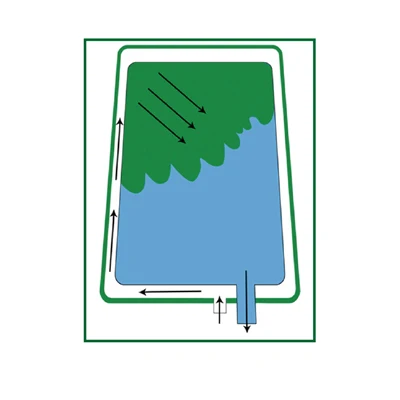

Schematic Diagram:

The steam generator heats to the optimum temperature when the sterilization program started. The distilled water is pumped into the generator and converted into steam immediately, then the steam is injected into the cassette which is loaded with instruments to be sterilized. The polluted air in the cassette is exhausted after the steam is injected.